Standalone Engine Controllers

A standalone engine controller has the ability to perform all of its own engine monitoring and control functions from a single box. It does not require any outside assistance from body or chassis modules. As such, they are particularly well suited to race cars, hot rods, and classics where these outside modules seldom exist. Each standalone controller is designed to work with its own wiring harness with connections to the necessary sensors and outputs. Very little outside engineering is required to get most systems up and running on just about any engine.

The same standalone controller can often be used on a wide variety of engines from inline fours to V-8s or even rotary Wankels. This common architecture keeps production costs reasonable and allows the user to remove the hardware from one vehicle and install it in another by simply changing the programmable configuration and a few sensors in most cases. The general control logic remains the same. Lessons learned tuning a standalone controller on one application can often be applied toward another in the future.

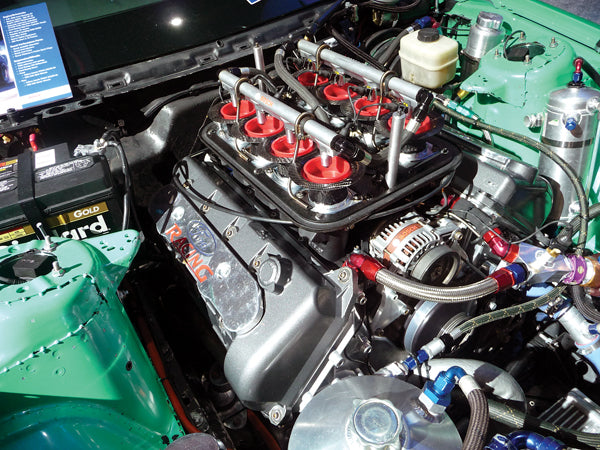

While this 240sx engine may look intimidating at first, to the experienced calibrator, it’s just another four-cylinder boosted engine. The standalone engine controller uses a 3 bar MAP sensor that can easily measure up to 30 psi of boost and calculate the large amounts of airflow and power that go with that boost.

This tech tip is from the full book, DESIGNING AND TUNING HIGH-PERFORMANCE FUEL INJECTION SYSTEMS. For a comprehensive guide on this entire subject you can visit this link:

LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook Groups or Forums/Blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.cartechbooks.com/blogs/techtips/standalonecontrollers

If the vehicle was originally equipped with a carburetor, there is often no option for a replacement factory controller. A standalone controller allows the user to add the flexibility of electronic controls by using the system’s own sensors and harness. The only wiring connections necessary to the rest of the vehicle are a 12-volt supply and ground. This make installation as simple as following the instructions included with most controllers and adding the proper high-pressure fuel-supply system. Similarly, racecars that have a few extra pounds of unnecessary equipment are easily equipped with standalone controllers. With the elimination of any unnecessary modules, their wiring harnesses and connections do not disturb the operation of the standalone EFI control system.

Since most standalone controllers are capable of working on inlet pressures of up to 3 bar MAP (more than 30 psi in the intake manifold!), they have no problem working with high-powered engines. Most standalone controllers also allow for engine speeds well beyond factory limits in production controllers, another key benefit to the racer.

An example of just how clean an EFI installation can be, this Ford could almost pass for carbureted if it weren’t for the aluminum fuel rails. This stealthy install still enjoys the benefits of EFI’s reliability with the classic look that suits the rest of the vehicle.

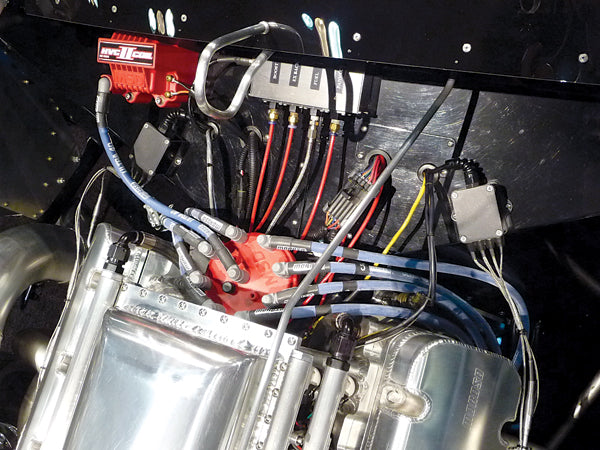

Another key to a clean installation, especially on a race car, is tidy wiring and terminals. Notice how each hole in the firewall is grommeted, wires are cut to length, and weatherpack connectors are used to avoid contamination.

Why Use a Standalone?

The primary reason for choosing a standalone EFI system is to add fuel injection to a vehicle where none previously existed. Updating carbureted engines to electronic control can improve efficiency, flexibility to weather changes, and overall drivability. The improvement in cold-start quality alone is enough for many to justify the change to electronic fuel injection. Adding fuel economy and better driving manners is often the icing on the cake here.

Another common reason for running a standalone controller is to upgrade from a factory ECU that has limited flexibility. If one does not have proper access to all of the calibration maps in a factory ECU, it can be utterly impossible to get some hardware combinations tuned properly. It can be an extremely frustrating experience attempting to tune around the factory setpoints only to have your final work “leaned out” by automatic correction strategies. There are many layers of control within modern OEM engine controllers. Without access to all of them, it can be a fruitless effort to attempt tuning. With some vehicles, there are no aftermarket tuning solutions whatsoever for the stock ECU. A popular choice here is to install a “piggyback” controller that intercepts and modifies the signals going to and from the factory ECU. This is at best a compromise, and often leads to the same concerns as tuning with only limited ECU access. Bypassing these systems entirely with a standalone engine controller can open the doors to a properly running vehicle, even at significantly elevated power levels.

Many late-model vehicles cannot simply have the engine controller removed and replaced with a standalone controller so easily. Modern CAN messaging networks check for the presence and feedback of each module on the communication bus and will not operate properly without all modules communicating as expected.

The key in this case is to ensure that the removal of the factory ECU does not wreak havoc upon other modules within the vehicle. There are often safety checks performed not only by the ECU, but by body controllers that may trigger “limp home” conditions if left unaddressed. When installing a standalone controller in a production vehicle, it is important to do your homework regarding what modules interact with the ECU. In some cases, it is possible to just leave the factory ECU on the harness to make the proper connections, but still have the standalone controller entirely in control of engine functionality.

So What’s In It for Me?

Standalone EFI systems have several key benefits over some other alternatives. First and foremost, they’re relatively simple in design and operation. While still complex when compared to a carburetor, the intricacy of modern OEM electronic controls makes the average standalone look like child’s play in comparison. Standalone EFI controllers usually only have a few layers of control at most. This makes adjustments much simpler for the end user. The simplicity extends to the installation and integration of the controller into the vehicle. Because the standalone ECU does not need any outside communication to run the engine correctly, the setup process is streamlined.

Since most standalone controllers operate on the speed density principle, they are exceptionally forgiving of intake system design. Almost any combination of air filter, tubing, throttle body, and manifold can be employed. There is no need for a MAF sensor, so even multiple intake paths can be used on a single engine. Likewise, the absence of the MAF sensor means that it can never be the limitation in either range or flow capacity for the engine. Many classic car owners prefer to discretely hide the EFI system under what, at a glance, appears to be an original round air cleaner atop a carburetor.

Speed density systems also have the benefit of being pressure-based controls. This means that even if the local barometric pressure changes, the EFI controller has the ability to automatically adjust. Even better, if used in a turbo or supercharged application, the speed density control system can tolerate pretty much any airflow amount imaginable as long as the system’s MAP sensor is within the measurable pressure range. Fortunately for the speed freaks of the world, 2 bar and 3 bar MAP sensors are both readily available and affordable. In short, the sky’s the limit for horsepower as long as you can measure the pressure.

Race cars like this Formula D Mustang are an ideal environment for a standalone EFI controller. The Bosch system used on this 5.0 L cammer engine runs an Alpha-N configuration to work better with the stack intake configuration and individual throttle bodies.

The classic look of the 14-inchK&N filter can still be maintained with a clean EFI installation. Much of the wiring for this GM LS engine is hidden in the valley beneath the single plane intake manifold.

Written by Greg Banish and posted with permission of CarTech Books

LEARN MORE ABOUT THIS BOOK

If you liked this article, you will LOVE the full book!

Click here to get your copy.