Mopar B-Body Knuckle Interchange

Chrysler equipped Mopar B-Body cars with subpar drum and inefficient disc brakes, and therefore, one of the best ways to improve performance and safety of a B-Body car is to install later-model OEM disc brakes or aftermarket disc brakes. In order to accommodate the newer disc brakes, you often need to convert the front spindle or knuckle. Therefore, you need to understand the features and interchangeability of the front knuckles for the B-Body brake swaps.

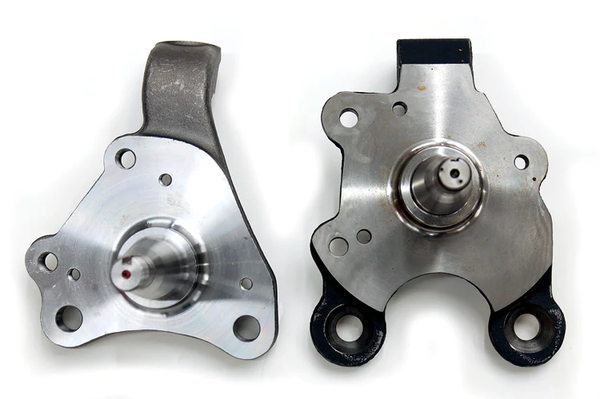

If you cannot find original big-bearing disc brake knuckles in your local salvage yard, you can purchase reproduction knuckles, as shown on the left. Magnum Force makes the 2-inch dropped knuckle on the right. The Magnum Force knuckle is designed to the same specifications as the 1973 big-bearing design, so all of the uni-cast brake parts swap over to this knuckle.

This Tech Tip is from the full book: MOPAR B-BODY PERFORMANCE UPGRADES 1962-1979

Learn everything you need to know about upgrading your Mopar B-Body by getting your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy this link to share:

https://www.cartechbooks.com/blogs/techtips/knuckleinterchange

B-Body vehicles from 1962 to 1972 used a short front knuckle with a small 1.250-inch-diameter inner wheel bearing surface. In 1973, the inner wheel bearing diameter increased to 1.375 inches, and the overall height of the knuckle was increased by roughly .375 inch. Although the spindle diameter was only increased by 10 percent, it reduces the bending of the spindle by almost 50 percent. The earlier Mopar spindles weren’t known for breaking, but a 50-percent increase in stiffness seems well worth a very slight increase in weight.

The 1970 to 1972 B-Body disc brake knuckle on the left looks very similar to the 1973 A-Body knuckle on the right. The primary difference is the size of the inner wheel bearing. The spindle on the left uses a 1.250-inch-diameter inner wheel bearing, while the bearing size on the right-hand spindle is 1.375 inches.

The upper ball joint taper, as well as the bolt pattern for the lower ball joint, stayed the same for all years of B-Body production. Due to the ball joint dimensions staying the same over the years, any B-Body knuckle bolts into any B-Body car.

The tall big-bearing knuckle has casting numbers 3402638 and 3402639. These knuckles came on late-model B-Body cars, as well as all of the FMJ vehicles. The short big-bearing knuckle from a 1973-or-newer A-Body or E-Body vehicle has casting numbers 3402627 and 3402626.

Although any knuckle bolts into any car, the difference in knuckle height between early- and late-model vehicles has caused a certain amount of controversy over the years. Some people believe that the 1962 to 1972 cars should only be retrofitted with short knuckles because that is what they were designed to work with. Those in this camp point out that the taller knuckles might cause the upper ball joint to “over angle,” or that the suspension geometry is harmed by the taller knuckle.

The adapters are available for pin-type and slider calipers. The bolt pattern is the same, so the adapter type can be changed, if necessary. Both adapters are available in two heights to work with the 11- or 113⁄4-inch rotor. One fact that isn’t well known is that there are also heavy-duty versions of the adapters, which are thicker and use longer mounting bolts.

Others tout the benefits of the taller knuckles, including lighter weight and a better camber curve. People in this camp also point out that vendors sell “tall knuckle” conversions for various GM muscle cars with the intent of improving the suspension geometry. On a personal note, I’ve used the taller knuckles on several cars and have never seen a problem, but, of course, that is not definitive proof.

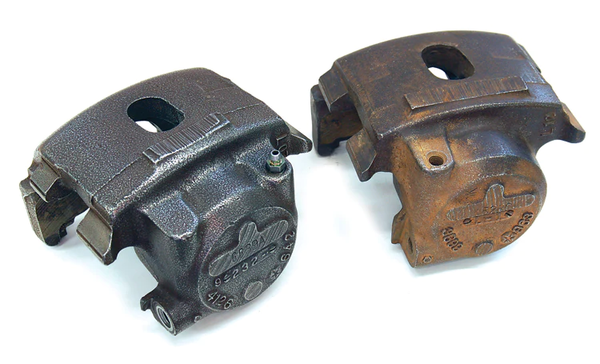

Both of these caliper castings are designed to be used on the driver’s side of the car. The housing on the left is a rear-hung design, while the one on the right is a front-hung design. The bleeder always has to be at the highest point on the housing, and the hose fitting should be pointed to the rear.

Although the debate is somewhat interesting, there are practical answers for people in both camps. For those who wish to stay with the shorter knuckles on the 1962 to 1972 cars, they are in luck, because the 1973 to 1976 A-Body cars came with exactly what they need. These A-Body cars, as well as E-Body cars after 1973, came with short knuckles that had the larger inner wheel bearing surface. So by using the A-Body knuckles, an owner of a 1962 to 1972 B-Body car can install the later-model uni-cast rotors without changing the front suspension geometry. If you cannot locate the correct A-Body knuckles used, new knuckles are available from a variety of vendors. Magnum Force even sells a version of these knuckles with a 2-inch drop for those who want to drop the front ride height.

Chrysler started to use phenolic pistons in 1975. They are lightweight, corrosion resistant, and insulate the brake fluid from the hot brake pad. These are 300 grams lighter than the standard chrome pistons. Using phenolic pistons in both calipers saves 1.3 pounds of unsprung weight on the front suspension.

For those who want to try the taller knuckles, reproductions are not available, so used parts have to be found. Fortunately, Chrysler engineers used the same tall knuckles under the 1977 to 1988 FMJ cars as they did on the 1973-and-newer B-Body cars. These FMJ cars are still fairly easy to find in wrecking yards, and the front knuckles are usually fairly easy to remove. For those who want to use the taller knuckles but are worried about the possibility of over-angling the upper ball joints, Firm Feel makes upper A-arms that have the upper ball joint slightly tilted. These conversion upper A-arms move the ball joint position slightly so it stays within its range during full suspension travel.

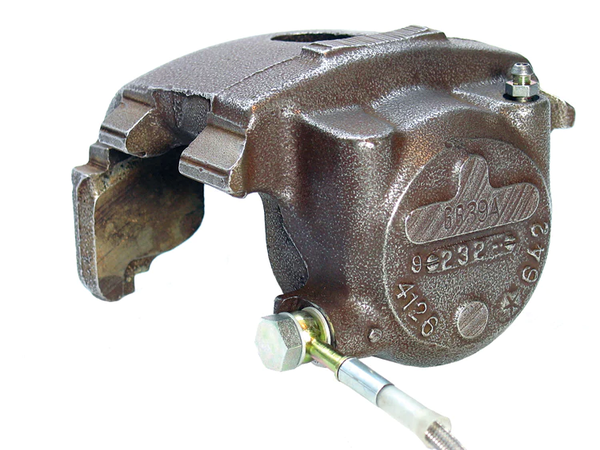

This is a rear-hung slider housing designed for driver’s-side use. There aren’t any stock hoses that fit these calipers properly on a B-Body, so custom hoses need to be used. Shown is a stainless steel hose with the correct banjo fitting. DoctorDiff sells these hoses, or they can be purchased from a brake hose dealer.

Once you have selected the knuckle that’s compatible with the disc brake setup you will use, you need to install the knuckle, brake rotor, caliper, and all the related parts. When you have accomplished this, your B-Body car will brake far better than before.

Written by Andrew Finkbeiner and Posted with Permission of CarTech Books

IF YOU LIKED THE THIS ARTICLE,

YOU WILL LOVE THE FULL BOOK!