Muncie 4-Speed Transmissions: How Muncie 4-Speeds Work

by Paul Cangialosi

It is a good idea to understand the basics of your Muncie 4-speed before you start rebuilding the transmission. Successfully diagnosing transmission problems is directly related to how well you understand how this transmission works.

This tech tip is from the full book, MUNCIE 4-SPEED TRANSMISSIONS: HOW TO REBUILD AND MODIFY.

For a comprehensive guide on this entire subject you can visit this link: LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook Groups or Forums/Blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.cartechbooks.com/blogs/techtips/how-muncies-work

Forward Gears

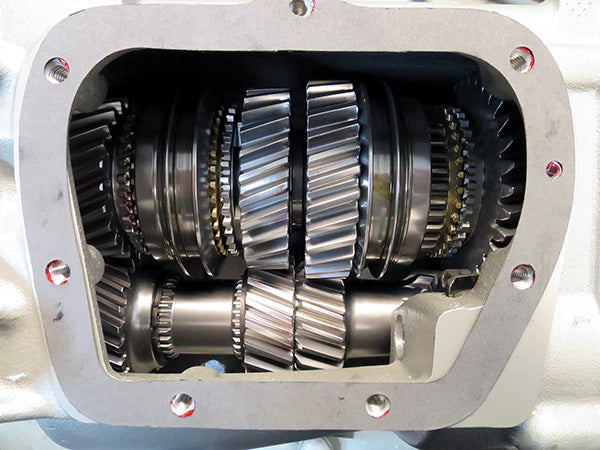

The Muncie 4-speed is a constant-mesh transmission. This means that all the gears in the transmission, except for reverse, are always meshed together and spinning, even in neutral. When you shift you are locking a particular-speed gear to the mainshaft. In reality, only three reduction gears correspond to physical first, second, and third gears. Fourth gear is technically a direct drive, so no physical gear is actually being used.

All forward-speed gears are locked to the output shaft via the two synchronizer assemblies; each assembly is responsible for working two gears. The rear assembly is the 1-2 and the front assembly is the 3-4. The cover has two shifter shafts that operate the forks, which then control the corresponding assemblies. The rear shaft works the 1-2 synchronizer fork; the forward shaft works the 3-4 synchronizer fork. The cover mechanism has detents that position and lock the shift fork in place. These detents function as interlocks, preventing any two forward-speed gears from being shifted at the same time. These also scissor in the sidecover.

Keep in mind that grabbing two gears at the same time can be extremely dangerous. In addition to blowing up the transmission, the driver can lose control of the car. When a shift is made, the shift fork moves the slider and the slider moves the three strut keys (or shift dogs). Finally, this energizes the synchro ring onto the gear. The synchro ring is locked to the synchro hub, which is then locked to the output shaft. Therefore, the ring matches the speed of the gear to the speed of the output shaft. (The ring is essentially a tapered cone clutch.) As the ring is forced against the cone of the gear the gear’s speed is matched to the speed of the output shaft and the slider continues to lock the gear to the shaft. This action all happens in a split second.

The inner workings of a Muncie 4-speed can be intimidating at first. Once explained, you will see that it is quite easy to understand how every component functions.

Reverse Gears

Reverse gear is a sliding gear. It has no ability to synchronize; therefore, you can only put a car into reverse when you are at a complete stop. The shifter shaft in the extension housing is the reverse shaft. The problem with this design is that it is very possible to shift into reverse and one of the forward-speed gears at the same time because no interlock mechanism is present. This doesn’t happen often, but sometimes a bent shift rod may rub against another rod and you lock up the transmission.

Many people grind reverse because they are too impatient to wait for the transmission to slow down on its own. Sometimes people put the transmission into first gear to make sure the transmission has stopped turning before putting it into reverse. This is a pretty good practice providing you have proper clutch release to begin with.

Clutch release can also be checked using what I call a “reverse-gear spin-down test.” Get your car good and warm so that all parts are hot and expanded while the engine is idling. With the transmission in neutral, press down on your clutch pedal, count off 10 seconds, and then put the transmission directly into reverse. This should be enough time for the transmission to slow down on its own so if there is any type of grind or clunk, the transmission is still turning when it should not, indicating poor release.

A clutch that releases poorly is the most common cause of synchro ring failure. In order for a synchronizer ring to do its job properly, it must be able to sync up the shaft and gear speeds with no engine load on it. If load is present, the ring overheats as it tries to fight the engine load; this causes the ring to warp.

The problem of falling out of gear is frequently misdiagnosed; people are very quick to blame synchro rings or shifter adjustment. Usually the cause is simply physical wear on the shift fork, the slider fork groove, the slider splines, and gear engagement teeth. Because the sidecover has positive detents these transmissions always shift into gear correctly with the shifter. The cover mechanism is very efficient in making sure that the shift fork moves the slider the correct amount. Basically, the cover is either in gear or its not; there is no adjustment. The only adjustment possible with this type of transmission is a linkage adjustment for a clean neutral gate.

This tech tip is from the full book, MUNCIE 4-SPEED TRANSMISSIONS: HOW TO REBUILD AND MODIFY.

For a comprehensive guide on this entire subject you can visit this link: LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook Groups or Forums/Blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.cartechbooks.com/blogs/techtips/how-muncies-work