Fuel System Math in Racing Engine Design

To calculate and service the requirements of your engine’s fuel system, you need a basic understanding of brake specific fuel consumption (BSFC), fuel flow requirements, injector sizing, jet area calculations, pump sizing, and other factors that affect how your engine burns fuel and how to optimize your fuel system. You’ll find that you use the formulas in this chapter more frequently than the primary engine building formulas because the information presented here affects how you operate and tune the high-performance engine you strived so diligently to construct.

For a comprehensive guide on this entire subject you can visit this link:

LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook Groups or Forums/Blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.cartechbooks.com/blogs/techtips/fuel-system-math-in-racing-engine-design

Brake specific fuel consumption (BSFC) is frequently misunderstood. Many people mistakenly believe that it is an indicator of rich or lean fuel mixtures, but it is actually a measure of efficiency that indicates how well the engine uses the fuel it burns. More specifically, it is the rate in pounds of fuel per horsepower per hour that a given engine consumes to make power. There is a range of optimum efficiency for most engines, and BSFC defines that range.

As you may have already surmised, the term “brake” precedes it because BSFC is usually measured with an engine running on a dyno. BSFC figures are typically quoted for wide-open-throttle conditions, but it is also a measurable quantity that relates to fuel economy at part throttle operation. In the performance world, we use it to judge the efficiency contribution of various engine combinations and to predict certain requirements such as fuel injector flow rate.

A particular cylinder head may be found to make more power with less fuel, and that’s an indicator of higher efficiency, probably due to improved cylinder filling and a more efficient combustion chamber that extracts more energy from a given fuel mass. Guidelines for evaluating BSFC are well established and are frequently used to predict engine performance. One-half pound of fuel per horsepower per hour (0.50 BSFC) is the default norm for most calculations, but we can be more specific in many cases.

BSFC = observed HP ÷ observed fuel flow in pounds/hour

Or

Mass Fuel Flow = BSFC x anticipated HP

The following BSFC figures are typical of most modern performance engines:

0.48 to 0.55 Stock and medium performance engines

0.45 to 0.50 Performance engines with good heads

0.28 to 0.45 Most racing engines

0.35 to 0.38 Pro Stock style engines

0.55 to 0.65 Supercharged or turbocharged engines

Herein lies part of the problem with thinking of BSFC numbers as indicators of mixture ratios. At 0.37 BSFC a Pro Stock engine may be thought to be running too lean when, in fact, it is operating at the highest level of efficiency with a normal air/fuel ratio of about 13:1. In contrast, supercharged engines run richer mixtures to complement boost pressure and discourage detonation. They absolutely run richer; not because they are inefficient, but to complement specific combustion characteristics inherent to boosted applications, not the least of which is charge cooling and the need for more fuel to augment the greater volume of air being supplied by the supercharging device.

When evaluating BSFC numbers, lower is almost always better (even when supercharged, where a 0.55 is still more efficient that a 0.65), as long as the combination supports safe combustion without detonation or overheating. It should be noted, however, that any engine still needs to run at the air/fuel ratio that produces best power. That’s usually about 13:1 in normally aspirated engines and 11.6 to 12:1 in supercharged applications. You can’t just run an engine lean and expect to get a low BSFC number. Tune for maximum torque and let the BSFC indicate how efficiently you generate that torque. At an indicated BSFC of 0.50 and engine burns 0.5 pounds of fuel per horsepower per hour (lb/hr). If the engine makes 500 hp, that’s 250 lb/hr. If we’re talking observed or uncorrected horsepower the fuel usage on your dyno sheet should indicate 250 lb/hr. So let’s see how that works.

One important thing to remember when you are looking at BSFC numbers on a dyno sheet is that BSFC relates only to observed (uncorrected) horsepower at the flywheel. Corrected horsepower is a calculated prediction based on specific correction standards for localized atmospheric conditions. Corrected horsepower figures multiplied by indicated BSFC will not match the recorded fuel flow in pounds per hour. This sometimes confuses novice tuners who are reading from the corrected figures on a dyno page. In many cases it leads them to think that the dyno is incorrect, or even worse, cheating them. I have seen numerous clients question power numbers that don’t match BSFC numbers based on this incorrect assumption.

For component or system evaluation, any combination that increases BSFC is likely a poor choice and won’t normally provide a power (torque) increase even though it doesn’t necessarily effect a power loss. It simply means less efficiency and no gain with more fuel required to make the same power. When you hit upon a combination that lowers BSFC and increases VE, you’re moving in the right direction. A running engine is, in effect, the ultimate flow bench. It telegraphs its preferences in terms of BSFC and VE. Appropriate power gains typically follow if the engine favors the current component mix.

Sharp dyno operators equipped with air flow turbines prominently display BSFC and VE numbers on screen so customers can observe them in real time during test sessions. When comparing components such as cylinder heads, it is often instructive to compare the graphs of indicated BSFC and VE to see how different components stack up against each other with all other factors remaining equal. VE improvements are frequently accompanied by BSFC improvements. If you build and tune for these two factors power will rise accordingly. Modern dyno software permits dyno data to be displayed and printed many different ways. A typical dyno sheet might show the following data streams:

RPM • Corrected HP • Corrected TQ • BSFC Fuel A • Fuel B • Oil Pressure • Water Temperature

Many will also display an air/fuel ratio calculated from fuel and airflow measurements or, in some cases, a feed from an O2 sensor. Most tuners make adjustments based on power gains or losses and the proximity of the air/fuel ratio to the ideal ratio for best power. Sounds reasonable, but for the purpose of further insight and evaluation, it might be more instructive to track the following critical data on a second page:

RPM • TQ • A/F Ratio • BSFC • Airflow Fuel Flow • VE • MAP • BMEP

Note that all of the above closely model the engine’s performance based on physical properties and internal combustion fundamentals. This is the data that reveals what is really going on inside the engine. In case you forgot, MAP is simply manifold absolute pressure and BMEP is the calculated brake mean effective pressure or an indicator of average cylinder pressure. There are many different ways to look at dyno data. If you think about the processes involved in producing torque and horsepower, it becomes clear that a lot of valuable recorded dyno data is routinely overlooked. SuperFlow dynos and probably most other modern systems are able to offer clients a take-home version of the dyno software with all the recorded data for each test run. This allows you to use your own PC to study and evaluate all of your data and re-display it or graph it in ways that are meaningful to your goals.

If you are able to obtain your test data in this manner, I encourage you to take a close look at the information recorded and calculated on multiple data pages behind the primary page. Think about what all that data is telling you and how you might draw more informed conclusions by comparing it in graphic form. You’ll be surprised at what you can learn about your combination.

A brief example might be a comparison between two cylinder heads with similar components, but different port flow characteristics. If one head shows better on the flow bench, you would expect to see a VE increase and a favorable BSFC if the combustion chamber provides supporting efficiency. Positive improvements in VE and BSFC translate directly to power gained at the flywheel. Closer examination of critical dyno data often reveals additional insight about where and how these gains occur in the power band and how they are affected by other contributing factors.

BSFC standards are also used to calculate anticipated fuel system requirements such as fuel pump capacity and fuel-injector size based on static flow rate. BSFC is a critical indicator of engine efficiency and it is one of your most valuable tools for evaluating engine performance. To gain further insight into the function of these systems and the calculations involved, we’ll examine each of them separately.

Calculating Injector Size

Anticipated power levels are the basis for choosing an appropriate fuel injector size. The selection criteria are also based on injector static flow rate and the BSFC associated with the type of engine and its anticipated power level. Most injectors are static flow rated at 43.5 psi of fuel pressure or about 3 bar (1 bar represents 1 atmosphere, so 3 atmospheres would be 14.7 x 3 = 44.1 psi). Static flow is the flow rate achieved with the injector held wide open with steady-state fuel flow at the qualifying test pressure (43.5 psi). This provides a convenient method of flow rating different injectors, but it cannot be used in practice because the injector would remain on all of the time.

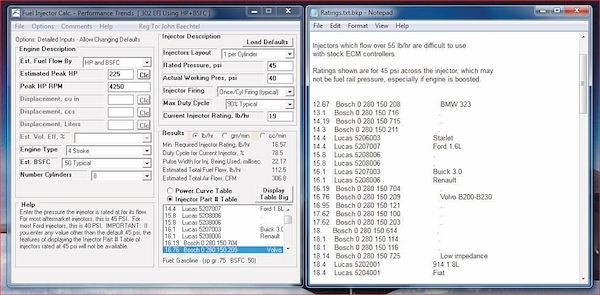

Performance Trends’ Fuel Injector Calculator calculates injector size requirements, pulse width and duty cycle, pressure corrections, and all related fuel-injection calculations.

Injector on time is called the pulse width. It is the length of time in milliseconds that the injector is open and flowing fuel per intake event. The critical factor here is the cycle time available for individual fueling events per cylinder. The intake valve opens once every other revolution, and the cycle time for fueling diminishes with RPM. The cycle time is the amount of time it takes for two complete engine revolutions with one intake fueling opportunity during each cycle. Engine speed determines cycle time in milliseconds and is calculated with the following formula:

Cycle Time = 120,000 ÷ rpm

So, for a 6,000-rpm engine speed:

Cycle Time = 120,000 ÷ 6,000 = 20 milliseconds

The ECU’s calculated injector pulse width must fit within this narrow window of fueling opportunity. If the ECU were to calculate a pulse width of 20 milliseconds, that would equal 100-percent duty cycle, which the injector can’t sustain because of injector head issues and the engine probably won’t tolerate. Hence a safety factor is incorporated into injector size calculations. The safety factor is typically 80 percent of the injector’s static flow rate, although some applications (Ford) use 85 percent. We’ll call it 80 percent, which means the injector can be on up to 80 percent of the available time or duty cycle.

Duty Cycle = [(injector pulse width x RPM) ÷ 120,000] x 100

Max Pulse Width = 120,000 ÷ RPM x safe duty cycle (80%)

Example for 6,000 rpm:

Max Pulse Width = 120,000 ÷ 6,000 x 0.8 = 16 ms

Duty Cycle = [(16 ms x 6,000) ÷ 120,000] x 100 = 80%

If the commanded pulse width exceeds the safe duty cycle the injector static flow is inadequate for the application. If the difference is small, it can be compensated for with additional fuel pressure, but the best solution is usually to select an injector with a higher static flow rate. This can get confusing because all injectors are not rated equally. While many aftermarket injectors are rated at 43.5 psi, Ford rates all their injectors at 39.15 psi, and most GM injectors are rated at 58 psi. The formulas all work the same, but you have to use the correct static flow rating for the injector you are considering. And its impedance must match the drivers in the ECU to prevent damage to the ECU because low-impedance injectors require more amperage to operate.

Factory systems such as Ford have used both mechanical and electronic returnless fuel systems to control evaporative emission since 1999. If you select injectors based on the factory rating and fuel pressure, you will satisfy all the requirements of the fuel system, which includes the ability of the Ford PCM to vary fuel pump voltage and pressure as required based on its knowledge of current operating conditions. When you have a choice of injectors rated at different flow rates, you can convert the flow rates at a different pressure delta with the following formula:

Flow Rate at Desired Pressure = flow rate at old pressure x √(new pressure ÷ old pressure )

Example: For a 30-lb/hr injector rated at 39.15 psi if you run it at 43.5 psi:

New Flow Rate = 30 x √(43.5 ÷ 39.15) = 31.6 lb/hr

Selecting an Injector

To size an injector we rely on the basic unit of efficiency, the brake specific fuel consumption (BSFC) at max power. For the purpose of calculation we use an estimated BSFC of 0.5 for normally aspirated engines and 0.65 for supercharged engines. We also incorporate the anticipated horsepower and a 20-percent safety margin, which gives an 80-percent operating duty cycle for the injector.

Injector Flow Rate = BSFC x HP ÷ number of injectors x safe duty cycle of 80%

If we anticipate 500 hp and a BSFC of 0.5 we can calculate the flow rate that will safely support that HP level.

Injector Flow Rate = (0.5 x 500) ÷ (8 x 0.80) = 39.06 lb/hr

A 39-pound injector will safely support 500 hp under all operating conditions. If, depending on your application, you need a specific type of injector (high or low impedance) and the only choices available are 36 or 42 pounds, select the larger injector to ensure the safety margin. If you are using the 39-lb/hr injector and dyno testing establishes that you are making 550 hp, you can preserve the safety margin by raising the fuel pressure accordingly. To calculate the required pressure increase we need to know the required flow rate to satisfy our safety margin at 550 hp.

Injector Flow Rate = (0.5 x 550) ÷ (8 x 0.8) = 42.96 lb/hr

If the rated flow of the 39-pound injector was established at, say, 43.5 psi, we calculate the required pressure to satisfy the new horsepower requirement as follows:

Fuel Pressure Change = (required flow rate x rated pressure) ÷ current flow rate

(42.96 x 43.5) ÷ 39 = 47.9 psi

If you raise the fuel pressure from 43.5 psi to 48 psi, the 39-lb/hour injector will support 550 hp at the safe duty cycle of 80 percent. You also need to enter the new flow rate into the ECU so it can make accurate calculations based on the new pressure. So if available injectors flow slightly less or more than required, small fuel pressure adjustments can bring them into line. The previous calculations can also be rewritten to determine the maximum safe horsepower that a given injector will support at its rated fuel pressure.

Horsepower = (injector size x number of injectors x max duty cycle) ÷ BSFC

To illustrate this examine the following examples taken from the Ford Racing catalog. Note that Ford uses a dutycycle safety factor of 85 percent for its calculations.

Naturally Aspirated at 0.5 BSFC = (19 lb/hr x 8 x 0.85) ÷ 0.5 = 258 hp at 85-percent duty cycle

Supercharged at 0.55 BSFC = (19 lb/hr x 8 x 0.85) ÷ 0.55 = 235 hp at 85-percent duty cycle

Supercharged at 0.65 BSFC = (19 lb/hr x 8 x 0.85) ÷ 0.65 = 199 hp at 85-percent duty cycle

Injector Flow Rate n/a HP Supercharged HP

(at 40 psi) (@ 0.5 BSFC) (@ 0.65 BSFC)

19 lb/hr 258 199

24 lb/hr 326 251

30 lb/hr 408 314

32 lb/hr 435 335

39 lb/hr 530 408

42 lb/hr 571 439

47 lb/hr 639 492

60 lb/hr 816 628

Note that these calculations are based on Ford injectors that are all rated at 39.15 psi. You can raise the pressure of any of these injectors to support more horsepower provided your fuel pump has the necessary capacity. Fuel pressure is set with an adjustable fuel pressure regulator that has a vacuum line connected to the intake manifold. This allows the regulator to hold a constant pressure drop across the injectors as manifold vacuum varies according to throttle position. The vacuum line from the manifold is connected to the reference side of the regulator diaphragm. It sees reduced pressure at idle or under cruise conditions. When the reference pressure drops, a corresponding drop in rail pressure occurs to keep the pressure drop across the injectors constant as manifold pressure fluctuates according to throttle and load.

The same thing occurs under boost pressure where each pound of boost causes a corresponding 1-pound increase in fuel rail pressure to maintain the pressure differential or “delta.” If the fuel pump and fuel system are sized to maintain this 1:1 ratio according to manifold pressure, the flow rate of the injectors increase proportionately with demand to maintain the necessary fuel flow under full boost at WOT.

Fuel Pump Capacity and Flow Rate

As previously discussed, calculations with BSFC and horsepower reveal an engine’s appetite for fuel in pounds per hour. Whatever that requirement might be, it represents the minimum steady-state fuel requirement at the injector or the carburetor. To ensure a positive reserve, fuel pumps are sized with plenty of capacity according to application.

To determine the required fuel pump flow rate for a given application, divide the calculated fuel requirement in pounds per hour by the nominal weight of gasoline, which is 6.009 pounds per gallon at a specific gravity of 0.72 and 65 degrees F. The specific gravity varies with temperature, but not enough to affect calculations for fuel pump capacity. There are two ways to calculate it: one for carburetors and one for injectors. The carburetor calculation typically indicates a lesser amount because it doesn’t incorporate the safety margin applied to keep the injectors operating at their proper duty cycle.

Flow Rateinj. = injector size x number of injectors ÷ weight of gasoline (6.09 pounds per gallon)

As noted in the previous example, 500 hp at a BSFC of 250 lb/hr. That represents the minimum requirement with the engine at WOT and maximum horsepower. To calculate the flow requirement, multiply the injector rating times the number of injectors and divide by 6.09 pounds.

Flow rateinj. = (39 x 8) ÷ 6.09 = 51.23 gallons/hour

The calculation is slightly different for a carburetor:

Flow ratecarb = (horsepower x BSFC) ÷ 6.09

For 500 hp:

Flow ratecarb = (500 x 0.5) ÷ 6.09 = 41.05 gallons/hour

When you see fuel pumps rated above the indicated requirement, it’s because the pump has to contend with the weight of the fuel in the fuel lines, g forces affecting the fuel mass, and fuel system restrictions such as injectors, carburetor needle and seats, fuel regulators, fuel filters, and the total number and type of fuel fittings in the entire fuel system. All of these factors conspire to restrict fuel capacity.

Accordingly, a good deal of overkill is required in pump selection. Bypass regulators are commonly used (except where previously noted) to reduce pumping effort while maintaining high-flow capacity. Pumps are required to supply the necessary volume at the appropriate fuel pressure, which can be anywhere from 20 to 70 psi for EFI systems and 5 to 12 psi for carburetors. A drag race car can generate substantial g force off the starting line; enough to literally stall the fuel column in the fuel line during peak acceleration. And supercharged engines create high fuel demands under boosted conditions with severe penalties if the fuel supply is inadequate. Accordingly, pump manufacturers build pumps with a substantial amount of reserve capacity to accommodate high fuel requirements. These calculations will help you determine the best pump.

If you know or have a good estimation of your car’s performance capability, Barry Grant (BG) Fuel Systems recommends the following low-buck test to confirm adequate fuel delivery. This test applies to drag racing cars, but it is well suited for other types as well since most other applications don’t generate the high g-loading and instant fuel demand under acceleration.

BG suggests using an inexpensive 1-gallon gas can to check the capacity of your pump. Disconnect the fuel line or lines from your carburetor and route them from the regulator directly into the top of the open can. Switch on your pump and clock the time it takes to fill the can. Compare your results to the ones below. If your car is not a drag car, you should still strive for the quickest fill time possible, especially on cars that endure long high-gear pulls at max power, i.e., Bonneville or superspeedway cars. BG has pumps and fuel systems to satisfy all of these demands.

Note: Exercise caution. Perform this test in an open air environment away from open flames. Keep a fire extinguisher handy and don’t try this alone.

One other thing to keep in mind for supercharged applications is the flow reduction that occurs when fuel pump pressure is increased under boost. This is also affected by available fuel pump voltage, which is frequently inadequate due to improper wiring or inadequate power source. This problem is most evident on EFI cars and must be addressed. Racing applications often datalog fuel pressure under maximum operating conditions to ensure that pump voltage and fuel rail pressure is adequate at all times. In most cases you have to generate this information yourself, but some manufacturers (Ford) have fuel pump maps that show flow rate versus delivery pressure at a given voltage.

Written by John Baechtel and Posted with Permission of CarTechBooks