Chevy Big-Block Performance: Electronic Fuel Injection Guide

At this time I have yet to complete my sixth EFI big-block. For that reason I am going to draw heavily on the experiences of ace fuel injection tuner Scott Clark. Having been fortunate enough to spend days at a time with this talented engine tuner I’ve learned about some EFI power moves that might have otherwise taken several years to discover. But first, let’s talk about EFI pros and cons.

Carbs versus EFI

In simple terms, there is fundamental calibration difference between carbs and EFI. You use your calibration skills to persuade the carb to produce the air/fuel ratios the engine wants. With EFI you program not only the air/fuel ratios the engine wants, but also the ignition timing it desires for optimal output.

An EFI system can be programmed with exceptional accuracy, and this uncovers less-than-obvious moves toward greater output. In some of my writings I have made a direct dyno comparison between a 4-barrel carbureted engine and a similar-style EFI–equipped engine with a 4-barrel throttle body. In every case, the car-bureted engine wins out in terms of WOT output. The primary reason for this appears to be that the carb introduces the fuel to the air at a more optimal point than does the usual EFI–port-injected setup. But there are also other contributory factors, such as atomization, distribution within each individual runner, etc.

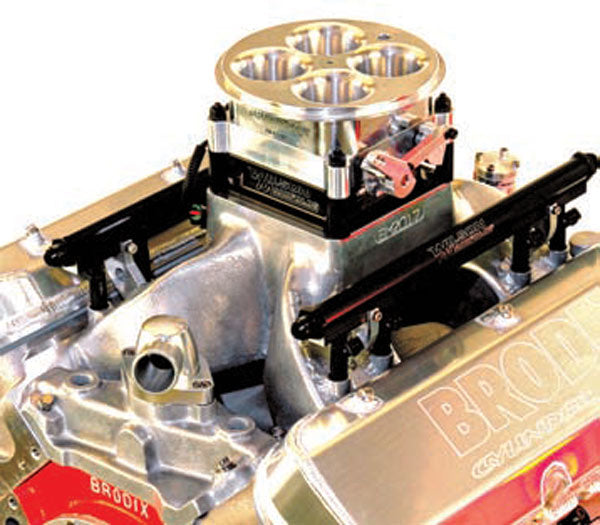

Fig. 8.1. With no boosters to inhibit airflow, this 4500 Dominator–style throttle body has the ability to flow about 2,000 cfm. Couple that with a good race intake such as this Brodix version to realize a formula for high output.

This Tech Tip is From the Full Book, DAVID VIZARD'S CHEVY BIG-BLOCKS. For a comprehensive guide on this entire subject you can visit this link:

LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook Groups or Forums/Blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.cartechbooks.com/blogs/techtips/chevy-big-block-performance-electronic-fuel-injection-guide

Fig. 8.2. Carburetors can deliver very good results, as did this BLP 4150–style carb on the street 565 engine shown here. This unit used a Dart block, with heads and intake by Brodix. Built by Throttle’s Performance, this 496 cranked out a civilized 700-plus hp. The question here is: What would it have done if spec’d for EFI?

Fig. 8.3. This aluminum-blocked 565 was built by Mark Dalquist of Throttle’s Performance with Brodix block, heads, and intake for a road-race Corvette displayed at the 2014 SEMA show. It was equipped with an Electromotive EFI system that sported a four-coil wasted-spark-style ignition system. After ace calibration specialist Scott Clark finished, this unit made a solid 880 hp with a 700-rpm idle.

In addition, we can draw on more than 60 years of development with Holley carbs and single-plane intakes. Considering all this evidence, why would anyone pay three to four times as much to get slightly less output? Well, you typically wouldn’t, but EFI system advantages are not readily apparent in a simple dyno comparison test. In practice, EFI has certain advantages over car-buretors. First, EFI has the capability to produce the best smooth and steady idle. Therefore, it’s practical to use a cam that is about 5 degrees longer before an acceptable amount of idle degradation is reached.

Second, the ignition timing curve can be tailored precisely to each individual cylinder, so the engine can, and this is important, run more compression because it is the first cylinder to detonate that limits the use of a single, mean, best-torque timing.

For example, if one cylinder starts to detonate at 28 degrees but all the others make their best power at 30 degrees, the 28-degree cylinder is the one that sets the limit. If you could set each cylinder separately, one would be at 28 degrees and seven would be at 30 degrees. Unfortunately, you cannot do this easily with a regular distributor and a carb. The engine would be stuck at one timing figure (28 degrees in this example) for all cylinders so seven of the cylinders would be short of their best.

Third, with a port-injected sys-tem, the fuel curve for each cylinder can be tailored to suit.

Finally, because an EFI system does not rely on intake manifold vacuum to atomize the fuel the drivability at small, street-use throttle openings is far better, as is the cold-start cycle. On top of that, with expert calibrations, bore wear from cold starts is virtually eliminated.

All of these factors mean that if you build from the outset to use EFI, you are in a position to have a streetable engine that makes more torque and horsepower along with having the potential of lower fuel consumption.

EFI System Variations

Fundamentally, you have three main types of fuel-injection systems. Let me give you a brief overview of each of them.

Injector Above Top of Throttle Body

GM’s throttle-body system from the early 1980s is the simplest. This type of system uses an injector posi-tioned above the top of the throttle body. This system typically runs at 14-psi fuel pressure rather than the more normal 45 to 50 psi with port injection. The atomization is a little too coarse for use on an unheated performance intake because it was originally intended for use with a heated induction system and a short cam. However, this can be partially offset by using a big-plenum manifold and throttle-body spacers that are 2 to 4 inches high.

Throttle Body on Tunnel Ram Intake

My EFI programmer guru, Scott Clark, had seen a pair of throttle bodies used on a tunnel ram intake. He reported some promising results and thought it an area well worth further research.

Also on this list is the MSD Atomic system, which injects the fuel at a booster in the throttle-body barrels much like a carb. I have yet to test this system, but it could have some great potential.

Throttle Body with Fuel Injection Below Butterflies

The next category of EFI is the throttle body with the fuel injection below the butterflies. Holley, FAST, and Professional Products have these systems. All such systems typically have self-programming features and the advantage of a simple installation. However, as far as output is concerned they are only as good as the fuel distribution qualities of the intake manifold. Unlike a carb, which can be stagger-jetted, compensating for cylinders too lean or rich due to manifold issues (and they always have them) is a little more complex.

Again, Scott Clark’s input here was a valued contribution. He has done a lot of calibration using the FAST system. He reports that the sys-tem itself works well, but unless the manifold is good, top results are not reached. Sometimes checking the flow of the individual injectors and placing them in the appropriate corner aids immensely in achieving an even fuel distribution. Failing that, using an ECM that can program each injector separately is the way to go.

Holley’s Terminator system is also a below-butterfly throttle-body injection system. Holley appears to have gone to a lot of trouble to achieve a fuel spray pattern and atomization that seems about as effective as a well-spec’d carb. This is another system that I have so far only used on small-block Fords, where it performed very well. How-ever, Scott Clark reports that it is effective on a big-block up to about 650 hp, which is the output limit of the injectors. Two pro engine build-ers who have the Holley system on their personal vehicles reported that the self-calibration feature worked well. After some fine-tuning, the systems drove like a custom carb with a virtually perfect setup.

Holley rates the Terminator for up to 600 hp, which may be a little low for most of the builds that follow my advice. This figure assumes a BSFC figure of 0.53, which is not that good. If you build to the specs I outline, especially in the cam department, you are likely to have an engine that delivers BSFC in the 0.43 range. That means Holley’s 600-hp rating can, in fact, be pushed to almost 750 hp.

Conclusions

Before deciding that a throttle- body system is for you, consider a few important aspects: First, do not expect to make more power with a throttle-body system than you can with a carb. As a straight swap, a well- set-up above-butterfly throttle-body injection system typically has a 20 hp difference in favor of the carb on a 600-hp engine. This performance difference between a fuel-injected engine and one with a carburetor can be reduced, but it is somewhat impractical as explained next.

To determine why an above- butterfly throttle-body system fell short of a carb, I ran a series of tests. The first move was to investigate whether or not the fuel was being atomized sufficiently. The engine, in injected form, was run at WOT. Then, for each subsequent test, the throttle was progressively closed by 3 degrees. This was continued up to 9 degrees of closing. The best power was shown at 9 degrees short of WOT. This indicated a mixture preparation problem. Next, 2-inch spacers were added one at a time. With four spacers for an 8-inch stack, the fuel-injection output closely approached that of the carb with one spacer.

Fig. 8.4. Holley’s Avenger system is a “plug-and-play” self-tuning system that works well with big-plenum intakes plus a spacer or with heated intakes. Idle, drivability, and throttle response are excellent, and it’s one of the least expensive systems out there.

Fig. 8.5. The FAST throttle body system has a self-calibration feature that puts the system close to optimum. The hand-held tuner can get you a near-perfect setup.

Fig. 8.6. Holley’s Terminator throttle body injection system is self-calibrating to a degree that will satisfy most needs, but for best results, fine-tuning is required.

Fig. 8.7. This cutaway of the Holley Terminator body shows the annular- discharge rings just below the butterflies. The pattern of fuel discharge produced by this design more closely emulates that of a carburetor.

Fig. 8.8. The FAST throttle body has four injectors, each of which discharges through two nozzles designed to finely atomize the fuel.

This Tech Tip is From the Full Book, DAVID VIZARD'S CHEVY BIG-BLOCKS. For a comprehensive guide on this entire subject you can visit this link:

LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook Groups or Forums/Blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.cartechbooks.com/blogs/techtips/chevy-big-block-performance-electronic-fuel-injection-guide

The conclusion is that the fuel droplets were too big and traveled faster than the air through the throttle body thus impinging on the intake floor and forming more unwanted rivulet flow than a carb. Throttle-body systems in which injection takes place below the butterflies also showed a similar trend, although more time testing is needed to quantify it.

If you elect to use a throttle-body EFI, do not go overboard on cam selection. You should select a cam that produces at least 10 inches of manifold vacuum at idle; a COS-Cam selection ensures this. Also, if you plan to have a computer determine how much fuel has to be injected, go that next small step and get a system that has control of the ignition timing. This allows you to make real gains in fuel efficiency, torque, top-end output, and drivability. Installed and set up properly, a throttle-body sys-tem can be a real pleasure to drive.

Port Injection

Port-injection systems are the way to go, but they’re not cheap. A fuel injector installed at a manifold location close to the cylinder head port seems like a big step forward over a carbureted system because it has the capability of ensuring an even cylinder-to-cylinder mixture distribution. In principle, that may be so, but with the current injector designs, such an injection point is usually too close to the intake valve, which results in a below-par mixture quality entering the cylinder.

The ideal point to introduce fuel to the air seems to be 12 to 15 inches from the valve. Although it is a very inconvenient situation, it is not insurmountable, but it introduces manufacturing problems.

ECU System

You need to keep in mind that the biggest obstacle toward making carbureted output is primarily the mixture preparation. If losses are minimized, the rest of what a port-injected EFI has to offer is positive. If a good choice of injector is made, and this can be a significant aspect, it’s down to the capability of the ECU. MegaSquirt, Holley, FAST, Electromotive, Accel, and Edelbrock have very capable ECU systems.

Fig. 8.9. Shown here is the Electromotive EFI system. All of the dyno tests have shown this to be a very capable system.

Fig. 8.10. According to independent industry experts, Holley has one of the top ECU systems on the market. The fact that it costs less than most is also appealing.

Fig. 8.11. Programming an Edelbrock EFI system is done either with a laptop or the included hand-held programmer. Note that the intake manifold is a version of the Victor Jr. carb intake but with injector bosses. Judging by TWPE dyno results, the oval-port version of this intake is very well suited to port-injection applications.

Fig. 8.12. Car builder Donavon Wagner (right) and I are getting ready to put this Mark Dalquist 565 onto Randy Torvinen’s dyno at Torvinen’s Machine. The engine subsequently went into a road-race Camaro that was on show at the 2014 SEMA show.

If you have never programmed a modern ECU, you will find that these systems allow the control of more parameters than you ever expected. My personal experience with port injection is limited to FAST, Accel, Electromotive, and Holley. Although the brand options and number of engines is limited, I have my own dyno so I can make tuning changes and test as long as I want. I make changes in fuel pressure, injection timing, the injector spray pattern’s constant flow, bank-to-bank injection, sequential injection, and many more parameters. At the end of the day it is evident that a well set up injection system can produce great results, but you need to utilize all the power of the ECU to achieve those results.

Tuning Strategies

Your big-block Chevy is not one V-8 engine, but instead eight different single-cylinder engines joined to form a V. With a typical single-plane, 4-barrel-style intake, early in the tuning procedure, you need to apply measurably different fueling and ignition strategies to each of the cylinders. Although situations vary, depending on heads and intake manifold, the front cylinders tend to run the coolest while the third cylinder back on each bank tends to run hottest.

In addition, the distribution of air within the intake is unequal, especially between cylinder numbers 5 and 7 (with a conventional firing order) and, to a lesser degree, between cylinder numbers 1 and 2. Also the length and shape of the runner from the plenum to the heads’ ports affects the air drawn into any particular cylinder. And if that is not enough, the runners’ approach to the head influences swirl. For the most part, the intake reduces swirl to one end of the head and increases it at the other.

All of these factors measurably affect the ignition timing needed for optimum results, and the result is quite significant. With a conventional distributor, an ignition swing only makes a small difference in out-put when making a timing change as much as 4 degrees. But this situation looks better than it really is, so don’t delude yourself into thinking the amount of power involved cannot be much. During the timing swing, some cylinders burn the charge more effectively and others do not. Although this looks contradictory, it is not the case.

EFI versus Carburetion

All the previous discussion and speculation leads to the inevitable question: What is an EFI system is worth over a carb? To answer this, it is necessary to take into account all of the advantages of EFI use, such as slightly bigger cam, more compression, individual cylinder tuning, more airflow, etc. As you may suspect, building two engines to make such a comparison is a very costly endeavor. Fortunately, I can present some data that will be a good guide.

A true street build typically has a 230-degree cam at 0.050-inch lift and a 10.5:1 CR. Examining the test results, at 3,000 rpm the torque output is consistently around 1.22 ft-lbs per cube and torque peak is at 1.39 to 1.4 ft-lbs per cube. Figure 8.17 provides the results of a test in which a 496 was built with an 11.2:1 CR instead of 10.5:1. Also, a cam of 236 degrees at 0.050 was used rather than one of 230 degrees. The results show a torque output at 3,000 rpm up to 1.26 ft-lbs per cube, and at peak torque RPM, the output is 1.435 ft-lbs per cube. The numbers indicate that an average increase of 2.5 percent in torque is a viable proposition.

Fig. 8.13. If an intake manifold, such as this Brodix version, is good when equipped with a carb, it will almost certainly be good with EFI.

Fig. 8.14. Holley’s Chevy big-block intake is a dedicated EFI design, rather than an adaptation of a carbureted intake. As such, it has been good on 500-inch engines but seems to show best when used on 540s and up.

Fig. 8.15. Looking into the plenum of the Holley EFI intake shows considerable design differences between it and intakes for carbureted use. The intake has a very consistent surface finish, which means virtually zero manifold work is required for optimum results.

Fig. 8.16. Here is the TFS-headed 496 built to test EFI when the rest of the engine spec is dedicated to its use. The injection/induction system employed an Edelbrock EFI intake (Victor Jr. style) plus an Edelbrock 1,000-cfm throttle body, fuel rails, and associated plumbing. An important part of the system was the actual fuel injectors. I took the advice of Injector Dynamics engineer Paul Yaw and installed injectors that he felt would have the best characteristics for the job. The distributor was an MSD unit that went along with the crank trigger setup. After calibration, the engine produced the curves shown in Figure 8.17. For full details on this build see page 140.

Fig. 8.17. You do not have to look through many magazine articles or ads to realize very few pump-gas–burning 496s with a 600-rpm idle crack the 700 ft-lbs mark, let alone make it to 721 hp. This build turned out so well that I felt I should have put this effort into a bigger build, such as a 540 or even a 572.

As for power, my engine builds with a 230-degree cam at 0.050 lift with a 10.5:1 CR and ported heads typically make between 695 and 712 hp. Figure 8.17 shows the EFI 496 test engine made 721 hp and 711 ft-lbs. The graph does not show the glass-smooth 600-rpm idle, the instant fire-up on a dead-cold start, or the far better BSFC at cruise throttle openings, which all translate to better mileage. In addition, it does not show the electric motor–like drivability and the really wicked throttle response.

So, do I like EFI? Sure, I do. Would I rather have EFI than carburetion? If it is for the street and the budget allows it, without question I would use EFI. Unfortunately, the budget is not always there, and if it is a race-only car engine, I am going to use a good old Holley Dominator.

Written by David Vizard and Posted with Permission of CarTechBooks

If you liked this article, you will LOVE the full book!

Get your copy here.